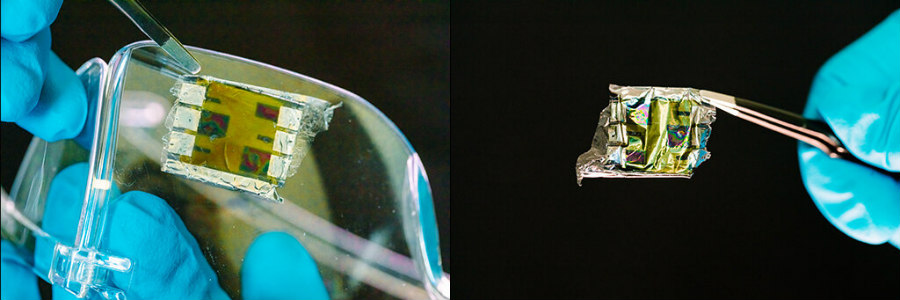

Credit: 2020 KAUST; Anastasia Serin

Scientists have made a solar panel so thin and flexible, it can perfectly rest on a soap bubble. Made with inkjet, it can efficiently harvest the sun’s energy. Scientists hope their breakthrough would be beneficial in a variety of applications where conventional power sources are not practical, such as “skin patches”.

According to Eloïse Bihar, lead author in the study, “The tremendous developments in electronic skin for robots, sensors for flying devices and biosensors to detect illness are all limited in terms of energy sources, rather than bulky batteries or a connection to an electrical grid, we thought of using lightweight, ultrathin organic solar cells to harvest energy from light, whether indoors or outdoors.”

Ultra-thin solar cells are not a novel idea. But its previous attempts are limited in scalability and geometry as they are built with thermal evaporation or spin-coating techniques.

The technique

They initially used a conductive and transparent, Indium Tin Oxide (ITO) electrode but at the same time inflexible and breakable which limited its progress. That is where the inkjet comes in. Researchers formulated a workable ink for each of the solar layers. Using inkjet printing and the easier of its scalability make the whole process very cost-effective.

But, the actual formulation of the functional inkjet had been a challenge for the researchers. “The intermolecular forces within the cartridge and the ink need to be overcome to eject very fine droplets from the very small nozzle. Solvents also play an important role once the ink is deposited because the drying behaviour affects film quality,” explains Daniel Corzo, a co-author of the study.

And instead of ITO, the researchers used their formulated inkjet and printed, “poly(3,4-ethylenedioxythiophene) polystyrene sulfonate” or PEDOT:PSS. It is a flexible, transparent and a conductive polymer which was just right for those thin layers of, organic photovoltaic, light-capturing layers. This functional unit was then covered with a thin, flexible and waterproof protective material called, parylene.

Credit: © 2020 KAUST; Anastasia Serin

Once the researchers were satisfied with the optimised ink printed solar unit, they tested it on a glass surface for the Power Conversion Efficiency (PCE). It recorded an astonishing 4.73% PCE surpassing the previous attempt of 4.1% PCE. And they also proved that these special solar cells can be printed onto ultra-thin flexible surfaces which gained a good 3.6% PCE.

“Our findings mark a stepping-stone for a new generation of versatile, ultralightweight printed solar cells that can be used as a power source or be integrated into skin-based or implantable medical devices,” says Bihar.

The study has been published in the journal, Advanced Materials Technologies