Credit: Chris LeBoutillier

Scientists from Japan have come up with a new generation, high-speed absorption separation method for carbon dioxide (CO2) from industrial gas emissions. There is a worldwide effort to figure ways on reducing greenhouse emissions to keep up with the expectations set by the 2015 Paris agreement. The target is to keep the global temperature level rise less than 2°C.

Industrial emissions are responsible for a large portion of the global greenhouse gas emissions. Either the massive use of industrial energy should be cut down or there has to be a highly effective and energy-saving separation method to capture CO2 from their gas emissions. Unfortunately, both of these methods are highly costly.

But now there is hope from Japan. After a long, thorough and successful study, scientists from Japan were able to create a very effective and high-speed absorption separation system which is also easy on the budget.

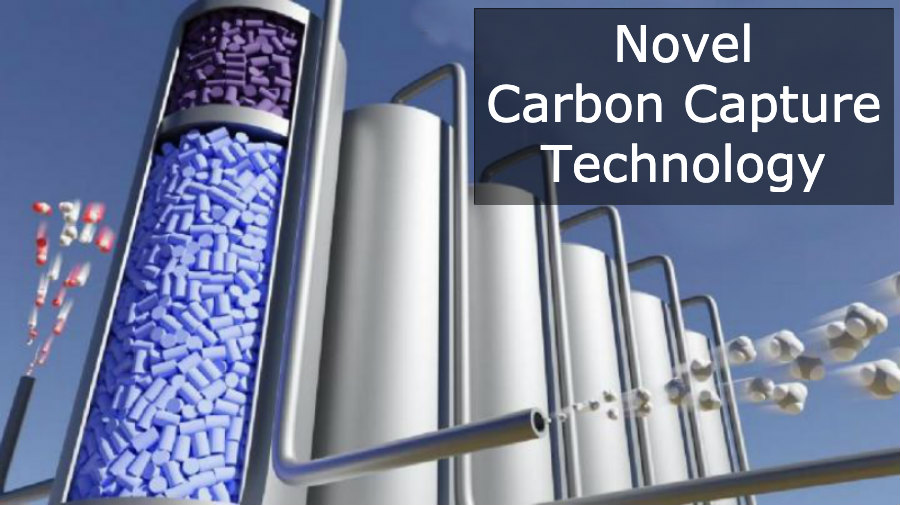

Credit: Shotaro Hiraide Ph.D., Department of Chemical Engineering, Kyoto University

About the method in use

The new technique is based on the absorption separation method. Some specific molecules can be absorbed in porous materials. The function in water filters is a good example for this. And in this study, scientists used absorbent (porous materials) filled towers. From one end, the industrial emitting gas enters and while inside the tower the separation process starts. Some molecules highly interact with the porous materials and they get trapped inside those tiny pores. But some other molecules can be weakly interactive, and they could be partially absorbed and/ or released.

For a fast-acting selective absorption, a stronger interaction is a must. And they found the right porous material that can absorb particular molecules effectively which could also desorb them as easily. So their gate-type absorbents were with ‘large loading capacity, high selectivity and minimal heat of adsorption all with a flexible structure’. It is called the ELM-11.

How does ELM-11 capture CO2?

This has a gate-type function that works on specific gas pressures. If the CO2 pressure or its contraction in the incoming gas mixture is below a particular level, the pores will stay closed and CO2 will not get absorbed. But when the CO2 is exceeding the threshold level, the pores rapidly expand and capture CO2 effectively. This opening and closing behaviour of the pores is the reason why its called the, ‘gate-type absorbent’.

When there is a low concentration of CO2, it does not get absorbed in the ELM-11 pores. So there is a chance that a little CO2 amount to be leaked out with CH4. To overcome the issue scientists used another absorbent called, HKUST-1. This absorbent is known to trap low-concentration CO2 gas better. So they placed HKUST-1 at the end of the absorption column to catch those escaping CO2 molecules.

This two-way absorption method has significantly reduced the tower volume, the amount of absorbents used and the energy used, which resulted in an extremely effective process.

What happens to the captured CO2 molecules?

The absorbed molecules would be separated by heating or depressurising the materials inside the towers. They used, pressure vacuum swing adsorption (PVSA) and temperature swing adsorption (TSA) processes for this and it is said to be more energy-efficient than distilling.

In this case first, ELM-11 contracts and releases all the captured CO2 molecules when the gas mixture has a low CO2 level which is below the threshold value. These released CO2 molecules are then separated by the above-mentioned methods and could be used for any other purposes.

In real-world industrial applications, this novel process works just fine with industrial high-speed gas emissions. The researchers believe that their process can be used effectively on thermal power plants and are currently finessing their process to be commercially applied. The study had taken 3 years to accomplish and the report has now been published in the journal Nature communications.