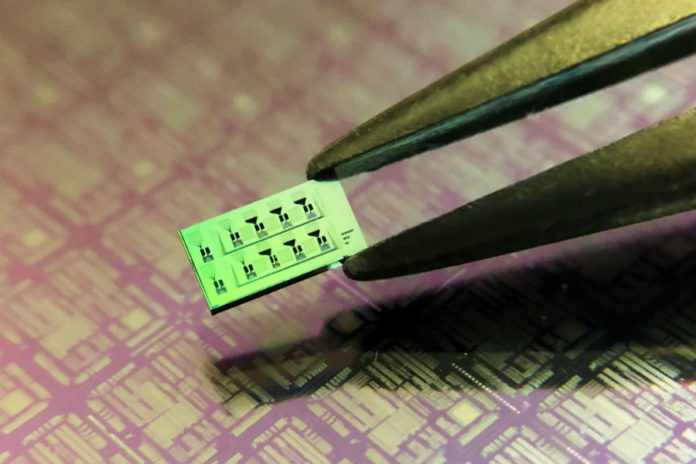

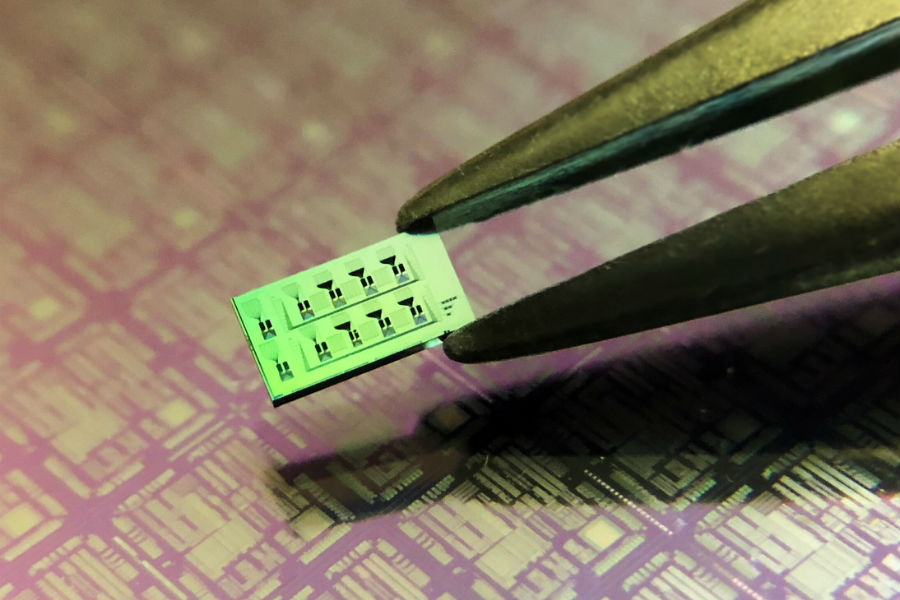

Credit: Helmholtz Zentrum Muenchen / Roman Shnaiderman

A team of scientists have developed the world’s smallest ultrasound detector which is about one-hundredth of a human hair strand. It is built upon a silicon chip that has mini photonics circuits on the top. And this micro gadget can also get super-high-resolution images in the smallest scale which was thought to be impossible before.

The conventional method of ultrasound technology uses piezoelectric detectors where the ultrasound pressure is turned into electric waves. This has been the case since its invent in the 1950s. The smaller the piezoelectric detector, the higher the imaging resolution.

Getting higher resolution, one or two-dimensional ultrasound images with smaller piezoelectric detectors was possible but up to a certain point. After that, the sensitivity of these piezoelectric detectors deteriorates dramatically therefore becoming not suitable for the job.

So, what is different in the new gadget?

Unlike the piezoelectric detector, this utilizes the benefits of silicon photonics technology. Having miniaturised optical parts condensed on top of silicon chips is now a widely used application in the industry. The role of the silicon chip here is to confine light which is smaller than the optical wavelength.

Using the above-mentioned technique to further miniaturise their product, the researchers were able to achieve the world’s smallest ultrasound detector called the “silicon waveguide-etalon detector (SWED)”. The gadget detects the smallest changes in light sensitivity that comes from the miniaturised photonic circuits.

According to Rami Shnaiderman, the developer and author of the study, “This is the first time that a detector smaller than the size of a blood cell is used to detect ultrasound using the silicon photonics technology. If a piezoelectric detector was miniaturized to the scale of SWED, it would be 100 million times less sensitive.”

How are the results?

The SWED can take super-resolution images. With the size of 0.0005 millimetres, it is 10,000 times smaller than a standard clinically used piezoelectric detector. And it uses 200 times smaller than the standard Ultrasound wavelength. This facilitates the imaging of minuscule structures of less than 1 micrometre.

The cost

Much cheaper to manufacture than standard piezoelectric detectors as it is mainly based on the robust production of silicon base. So mass production is easily achievable. And it also opens pathways to develop cheaper detection devices that are based on ultrasound.

“We will continue to optimize every parameter of this technology—the sensitivity, the integration of SWED in large arrays, and its implementation in hand-held devices and endoscopes,” says Shnaiderman.

The technology would be massively beneficial for industrial applications as well, although this was initially developed for the purpose of biomedical and clinical applications.

The study has been published in the journal Nature.